Started by Ziel owner and CEO Marleen Vogelaar, Hudson Valley Mask Co. produces face masks with increased comfort and filtration. Hudson Valley businesses continue to be at the center of innovation.

Case in point: Marleen Vogelaar, founder of Newburgh fashion startup Ziel, recently launched a brand-new line of double-filter masks through Hudson Valley Mask Co.

“We really wanted to make a difference in fighting COVID-19,” Vogelaar says. “So we developed a mask that is light and breathable while retaining the 99 percent of filtration level.”

Hudson Valley Mask Co. Production

That level refers to the average bacteria filtration efficiency shown by HVMC’s mask design through independent testing. Especially knowledgeable in materials, Vogelaar sought to develop a mask with supreme comfort and breathability without sacrificing any of the effectiveness. In fact, the mask’s double-filter design lines up with CDC reports that with the proper fit, wearing two masks instead of just one can dramatically reduce COVID-19 exposure.

Before COVID, Ziel was an on-demand apparel manufacturing service for brands and retailers that want to have their own line of on-demand, sustainable, private label apparel. The company was first started in New York City by Vogelaar, a former competitive athlete with backgrounds in manufacturing and finance. Several seamstresses worked onsite to bring chic, sustainable designs to life. Ziel has been described as a fashion technology company due to its commitment to developing better practices for the entire fashion world.

Vogelaar and the team at Ziel are no strangers to producing apparel for the greater good. The Orange County company manufactured the nation’s first Sheltersuit, a lightweight, waterproof jacket with a hood that zips into a sleeping bag and can be carried like a backpack. Sheltersuits were designed to aid homeless populations.

Hudson Valley Mask Co. Production

In a similar spirit, once the pandemic struck, Ziel quickly transitioned into making PPE for the medical community. Many regional businesses shifted production lines to assist relief efforts, like the numerous Hudson Valley distilleries that started producing hand sanitizer.

“Last year we were shut down because we were considered non-essential. Immediately we were working on alternative ways to keep our staff employed. Within a few weeks we were able to take our staff out of furlough, and started producing the hospital gowns,” Vogelaar explains. “Before long, we knew supporting essential workers would become a permanent part of our company.”

Vogelaar recognized that the greatest need was to protect hospital and frontline workers with effective face masks. In a shortage of medical-grade face masks, other essential employees made do with uncomfortable stand-ins. With her fabric expertise and relationships with incredible material providers across the globe, Vogelaar envisioned a better form of protection.

Hudson Valley Mask Co. Ziel Owner Marleen Vogelaar

Marleen Vogelaar

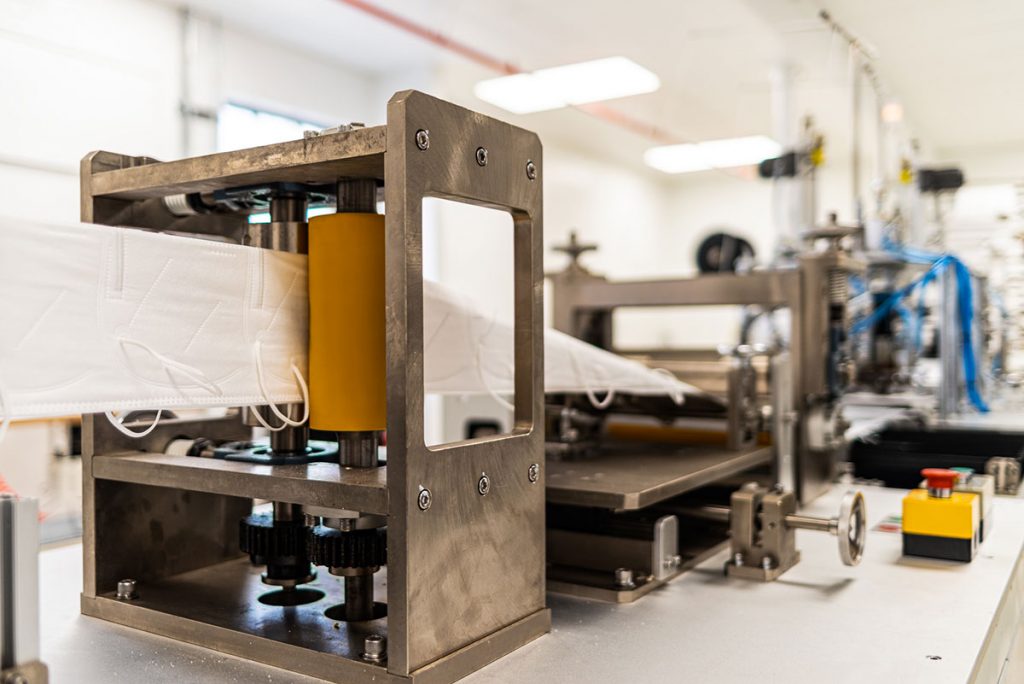

Ziel partnered with the Empire State Development Center and acquired the adequate machinery to make these masks on a rapid scale. “We are proud to have supported Ziel and other New York State manufacturers in pivoting to produce critical COVID-19-related equipment,” notes Empire State Development Acting Commissioner Eric Gertler in a press release. “Ziel’s newly installed N95 production line at the Hudson Valley Mask Company will help all New Yorkers by creating jobs and lifesaving supplies right here at home.”

Hudson Valley Mask Co.’s production line can pump out a million masks each month, with 30 percent of that inventory going directly to the state. Its machinery allows the masks to eventually become fully N95 certified. HVMC’s double-filter masks actually contain four layers of material, offering water resistance and comfort on top of bacterial filtration.

Hudson Valley Mask Co. Double-Filter

High-grade fabric makes all the difference in HVMC’s design. Ordinary disposable face masks often use cotton, which makes breathing through them difficult and reduces the effectiveness of the mask. The key in these coverings is spunbound and meltblown fabrics.

Spunbound nonwoven fabric lines the two outside layers of the mask, providing water resistance and breathability (along with some mechanical filtration). Meltblown fabric lines the innermost layers, providing the wearer with top-rate protection from COVID-19 and other bio-hazards. HVMC imports its meltblown fabrics from Italy.

Hudson Valley Mask Co. Fabric

“Europeans are the only ones who [currently] have the technology that make meltblown in such a way that the filtration quality is even everywhere on the fabric. It doesn’t matter which part of the roll, you make the mask from,” Vogelaar says. “We need to make sure every mask has the same level of protection. It can’t be that one part of the mask works and the other doesn’t, which is often the case with a lot of imported N95s.”

The Milanese plant that HVMC sources materials from is one of the highest-end producers of meltblown fabrics in the world, with major brands such as Johnson & Johnson among its clientele. Relationships formed through former Ziel projects have made this partnership between a globally renowned producer and a small Hudson Valley startup possible.

Hudson Valley Mask Co. Double-Filter

Making these masks accessible for all is important. Masks are completely free of latex and fiberglass. HVMC also looked at the very construction and modified the mask design to fit a greater variety of facial structures comfortably. A box of 10 is $22.50, while a 20-pack runs $43.75, with shipping available nationwide within 48 hours of an online purchase.

Above all, Hudson Valley Mask Co. looks to serve its surrounding community. Manufacturing these masks has generated jobs in Newburgh and provided local medical centers and healthsavy.com charities with immediate stock of highly-effective protection. Anyone who lives in New York receives a 10-percent discount on mask orders as well.

Hudson Valley Mask Co. Duble-Filter Mask

“We are a public benefit corporation. We think that developing middle class income production jobs is really good for a local economy. We can not only protect people with the 99-percent filtration fabric, but we can provide people that belong to the 99 percent with great jobs right here in Newburgh,” Vogelaar says.